Modernisation of traffic control, telecommunications and power supply systems on Lithuanian Railways’ IX D corridor

- Client Lithuanian Railways

- Implementation period 2009 – 2012

- Project location Lithuania

- Project partners AŽD Praha, Eaton

- Project task To carry out modernisation of the IX D railway corridor to improve both reliability and safety on this critical part of Lithuania’s rail infrastructure.

Solutions in this project

- Microprocessor-based traffic control system

- Microprocessor-based signalling system at level-crossings

- Diesel generators and uninterruptable power supply systems

- 10kV and 0.4kV power supply networks

- Electric point heating system

- Relay protection and SCADA system

- Illumination of level-crossings and platforms

- Technological loudspeaker communication system

- Staff warning system

- Security, fire alarm and gas suppression systems

- Video surveillance systems at level-crossings

- Data transmission system

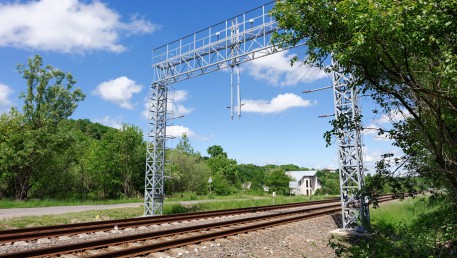

The project included the upgrading of traffic control, power supply and telecommunications systems on a 110 km section of railway.

As part of this very large and complex project, FIMA and its partners designed and upgraded the signalling, telecommunications and power supply systems at Kaunas station, on the Palemonas–Rokai–Jiesia detour and on the line between Kaunas and Kybartai.

The entire railway line connecting Kaunas, Kybartai and the Lithuanian state border with the Kaliningrad Region of the Russian Federation has been modernised with an up-to-date computerised rail traffic control system which enables the Vilnius Traffic Control centre to control the signalling and power supply equipment at all stations and level-crossings on the line and to control traffic on the line.

While installing the railway traffic control system, specialists from Fima and its partners carried out a number of specific tasks:

- centralised traffic control from Vilnius Traffic Control Centre was introduced at all the stations and on all parts of the line;

- centrally-controlled computerised systems with the option of local control were installed at all railway stations;

- all signalling equipment and related cabling were replaced;

- new signalling systems were installed at level-crossings;

- a reliable train positioning system was introduced;

- staff warning systems were installed in all stations to alert track workers of approaching trains;

- all of the new signalling and control systems were installed with reliable power supplies etc.

The completed project is unique in terms of its scale and complexity as well as the integrity of engineering operations implemented. The work was carried out by more than 200 professionals who were all experts in their particular fields. The project was implemented without stopping regular rail traffic on this intensive transport corridor.

The project has allowed the line speed to be increased to 160 km/h.

Project facts:

- 110 km railway line

- 8 railway stations

- 33 automatic control systems at level-crossings

- 430 traffic lights

- 20 10kV transformer stations

- 100 km of 10kV overhead and cable lines

- 2,000 km of cabling

- electric heating systems at 200 points

- Project period: 1,279 days

- More than 50 subcontractors managed

Project video

Related projects

-

Installation of railway systems on the Vilnius bypass section Pušynas–Paneriai

Installation of railway systems on the Vilnius bypass section Pušynas–Paneriai

-

Technology infrastructure solutions at Latvian shopping centre Akropolis

Technology infrastructure solutions at Latvian shopping centre Akropolis

-

Installation of intelligent transportation systems on road E67

Installation of intelligent transportation systems on road E67

-

Fire protection system of the Lithuanian Central State Archives

Fire protection system of the Lithuanian Central State Archives

-

An integrated solution for the surveillance and control of the EU border with Russia and Belarus

An integrated solution for the surveillance and control of the EU border with Russia and Belarus

-

Server room infrastructure for the new TV studio of Latvian National Television

Server room infrastructure for the new TV studio of Latvian National Television

-

Engineering solutions for the National Centre of Physical and Technological Sciences of Vilnius University

Engineering solutions for the National Centre of Physical and Technological Sciences of Vilnius University

-

Variable message traffic signs for regional roads in Lithuania

Variable message traffic signs for regional roads in Lithuania

-

Modernisation of signalling system on Liepaja Railway Station with reconstruction of Railway tracks

Modernisation of signalling system on Liepaja Railway Station with reconstruction of Railway tracks

-

Speed enforcement and display equipment in Smiltenė

Speed enforcement and display equipment in Smiltenė

-

Security system at the liquefied natural gas (LNG) terminal in Klaipėda

Security system at the liquefied natural gas (LNG) terminal in Klaipėda

-

Modernising East–West railway corridor

Modernising East–West railway corridor

-

E-ticketing system for Lithuanian railways

E-ticketing system for Lithuanian railways

-

Fire extinguishing system at IKEA plywood factory

Fire extinguishing system at IKEA plywood factory

-

Equipping a functional fire station at Vilnius Airport

Equipping a functional fire station at Vilnius Airport

-

Smart electrical grid sectioning facilities in the Klaipėda and Šiauliai regions

Smart electrical grid sectioning facilities in the Klaipėda and Šiauliai regions

-

Installing infrastructure at the border and customs inspection post at Vilnius railway station

Installing infrastructure at the border and customs inspection post at Vilnius railway station

-

Engineering systems at a water park in Minsk

Engineering systems at a water park in Minsk

-

Ionising radiation detection system at Klaipėda Seaport

Ionising radiation detection system at Klaipėda Seaport

-

Public transport priority system near Kaunas Railway Station

Public transport priority system near Kaunas Railway Station

-

Safety solutions for biofuel and waste-to-energy co-generation plant run by Fortum Klaipėda

Safety solutions for biofuel and waste-to-energy co-generation plant run by Fortum Klaipėda

-

Fire suppression solutions in the new Information and Communication Centre for Scholars at Vilnius University Library

Fire suppression solutions in the new Information and Communication Centre for Scholars at Vilnius University Library

-

Cabling infrastructure system at Microsoft’s Lithuanian office

Cabling infrastructure system at Microsoft’s Lithuanian office

-

Engineering solutions for GECO biofuel plant in Kaunas

Engineering solutions for GECO biofuel plant in Kaunas

-

Indoor positioning system to locate staff in a psychiatric hospital

Indoor positioning system to locate staff in a psychiatric hospital

-

Fire detection and extinguishing solutions in the Lithuanian Power Plant’s combined cycle block

Fire detection and extinguishing solutions in the Lithuanian Power Plant’s combined cycle block

-

Data Centre infrastructure for the Latvian State Radio and Television Centre

Data Centre infrastructure for the Latvian State Radio and Television Centre

-

Installation of traffic information system in Lithuania

Installation of traffic information system in Lithuania

-

Construction of a public health laboratory of Biosafety Level 3

Construction of a public health laboratory of Biosafety Level 3

-

Set-up and maintenance of a speed enforcement network

Set-up and maintenance of a speed enforcement network

-

Installation of data centre infrastructure for Lithuanian Railways

Installation of data centre infrastructure for Lithuanian Railways

-

Telecommunications and security systems in RIMI shopping centres

Telecommunications and security systems in RIMI shopping centres

-

Transit trains surveillance system on the line to Kaliningrad

Transit trains surveillance system on the line to Kaliningrad

-

Access control system for Minsk Automobile Plant

Access control system for Minsk Automobile Plant

-

Solutions for Centralised traffic control in Vilnius

Solutions for Centralised traffic control in Vilnius

-

A computer and telephone network for outpatient clinics across Vilnius

A computer and telephone network for outpatient clinics across Vilnius

-

Installation and maintenance of engineering systems in the Šiauliai arena

Installation and maintenance of engineering systems in the Šiauliai arena

-

Electronic perimeter security system at an oil terminal

Electronic perimeter security system at an oil terminal

-

Integrated engineering systems for the CIDO universal sports arena

Integrated engineering systems for the CIDO universal sports arena

-

CCTV in the town of Klaipėda

CCTV in the town of Klaipėda

-

Security system in Rokiškis psychiatric hospital

Security system in Rokiškis psychiatric hospital

-

Security solutions for a snow arena in Druskininkai

Security solutions for a snow arena in Druskininkai

-

An engineering systems solution for the new Lithuanian Parliament chamber

An engineering systems solution for the new Lithuanian Parliament chamber

-

Modernisation of telecommunication systems on Kaišiadorys–Kybartai railway section

Modernisation of telecommunication systems on Kaišiadorys–Kybartai railway section

-

Integrated project to install engineering systems in the Stasylos railway border inspection post

Integrated project to install engineering systems in the Stasylos railway border inspection post

-

Engineering Solutions in Kaunas rail tunnel

Engineering Solutions in Kaunas rail tunnel

-

Modernisation of Kaunas Airport’s runway light signalling system

Modernisation of Kaunas Airport’s runway light signalling system

-

Passenger Terminal Engineering Systems at Palanga Airport

Passenger Terminal Engineering Systems at Palanga Airport

-

Engineering systems in the new terminal at Vilnius International Airport

Engineering systems in the new terminal at Vilnius International Airport

-

Reconstruction of substations and power distribution station for Lietuvos energija

Reconstruction of substations and power distribution station for Lietuvos energija

-

Reconstruction of substation control systems in the Kėdainiai and Rokiškis regions

Reconstruction of substation control systems in the Kėdainiai and Rokiškis regions

-

Installation, upgrade and technical maintenance of a contact centre for Lintel

Installation, upgrade and technical maintenance of a contact centre for Lintel

-

Development of the Rural Areas Broadband Internet Network (RAIN)

Development of the Rural Areas Broadband Internet Network (RAIN)

-

Server room infrastructure for Danske Bank

Server room infrastructure for Danske Bank

-

DNB Bank offices security and information systems

DNB Bank offices security and information systems

-

Integrated security system for SEB Bank

Integrated security system for SEB Bank

-

Fire extinguishing system in an Intersurgical plant

Fire extinguishing system in an Intersurgical plant

-

Security and building management system in the EUROPA shopping centre

Security and building management system in the EUROPA shopping centre

-

Population warning and notification system in Šiauliai

Population warning and notification system in Šiauliai

-

Vilnius video surveillance system

Vilnius video surveillance system

-

-